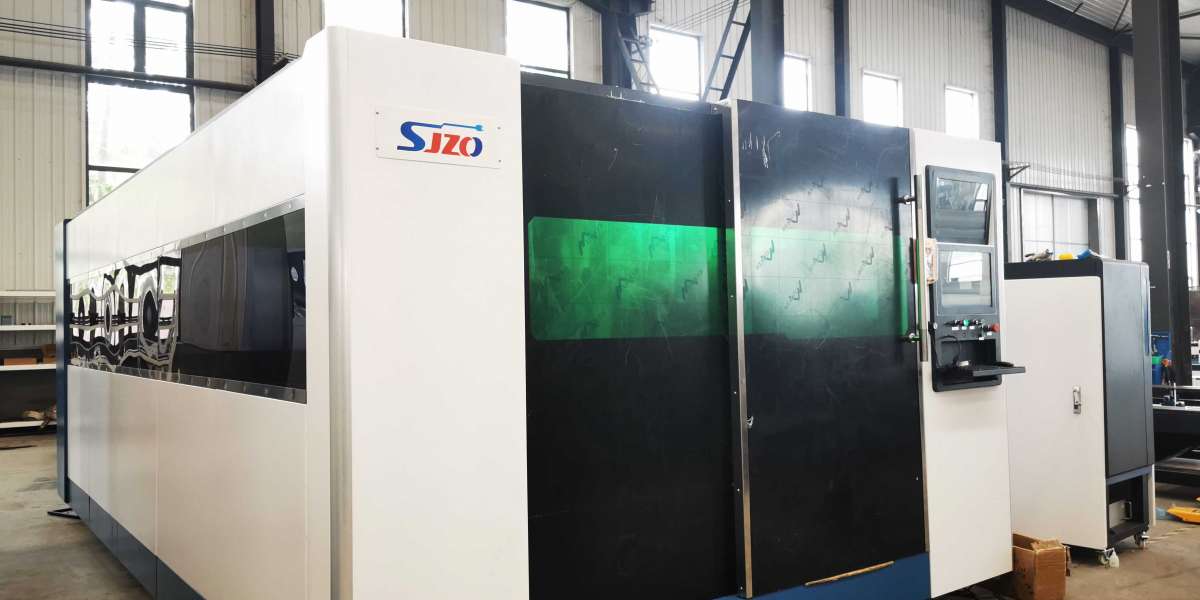

Today, many companies use lasers to weld parts together during the manufacturing stage of product design. These companies come from many industries such as medical, automotive and aerospace. There are many reasons why laser welding is increasingly becoming the technology of choice in these industries.

To help new users understand why laser technology is the best welding solution for manufacturing companies, we have summarized the following five main benefits for you:

1) Consistent and repeatable weld

Manufacturers choose laser as their first choice of welding method because it can perform consistent and repeatable welding. It is a much faster welding technique than other more traditional techniques, and it has a wider range of uses.

The same laser can also be used for cutting and drilling (pulse fiber lasers can also be used for marking). The fact that lasers have excellent repeatability and a wide range of uses can help companies significantly reduce unit costs.

2) High strength weld

Laser technology enables manufacturers to perform high-strength welding. No filler material is required. Lasers have excellent welding quality and clean processing technology, which is why lasers are favored by manufacturers, especially in the medical industry where the safety of medical equipment and parts is critical.

3) Low-calorie applications

The fact that laser welding technology uses low heat minimizes component deformation. This is why it is the preferred welding method for manufacturing luxury items such as custom jewelry. Lasers use very local energy, so non-contact applications can be performed, thereby reducing thermal strain on the parts.

4) Ultimate accuracy

One of the main advantages of laser welding is that it provides a high level of accuracy and control. The fact that laser technology is so precise means that it can be used to weld the smallest parts together without causing any damage.

5) Ability to create complex connections

Laser technology can handle complex connections. Using laser welding technology, you can weld different materials and areas that are difficult to reach using traditional welding techniques.

For more information, please visit https://sjzqlaser.com/key-products

Media Contact

Company Name: Zhongqu (Shandong) Intelligent Equipment Co., Ltd.

Contact Person: SJZQLASER

Email: marketing@sjzqlaser.com

Phone: 86132103

Country: China

Website: https://sjzqlaser.com