Tetrahydrofuran (THF) is a vital chemical compound widely used in various industrial applications, including solvents, polymers, and pharmaceuticals. As demand for THF continues to rise, understanding its production costs becomes paramount for both producers and consumers. In this blog post, we delve into the intricacies of THF production costs, exploring the factors influencing them and the importance of comprehensive cost analysis reports in the industry.

Request Free Sample: https://www.procurementresource.com/production-cost-report-store/tetrahydrofuran/request-sample

Tetrahydrofuran Production:

THF is primarily produced through the catalytic hydrogenation of furan. This process involves several stages, including feedstock preparation, hydrogenation reaction, purification, and product recovery. Each step contributes to the overall production cost, making it essential to analyze them individually to optimize efficiency and reduce expenses.

Factors Influencing Tetrahydrofuran Production Costs:

Raw Material Prices: The cost of furan, the primary raw material for THF production, significantly impacts overall production costs. Fluctuations in furan prices, influenced by factors such as supply-demand dynamics and feedstock availability, directly affect THF production expenses.

Energy Consumption: THF production processes require substantial energy inputs, particularly during hydrogenation and purification stages. Energy costs, including electricity and fuel, play a crucial role in determining production expenses.

Catalysts and Chemicals: Catalysts are essential for promoting the hydrogenation reaction in THF production. The cost and availability of catalysts, as well as other chemicals used in the process, influence production costs.

Process Efficiency: Improving process efficiency through technological advancements and optimization measures can help reduce production costs by minimizing resource wastage and increasing yield.

Tetrahydrofuran Production Cost Analysis:

Conducting a comprehensive cost analysis is essential for producers to identify cost drivers, optimize resource utilization, and enhance profitability. A detailed cost analysis report provides insights into various cost components, allowing stakeholders to make informed decisions and implement strategies for cost reduction and efficiency improvement.

Key Components of Tetrahydrofuran Production Cost Analysis Report:

Raw Material Costs Breakdown: Analyzing the contribution of furan and other raw materials to total production costs.

Energy Consumption Analysis: Assessing energy consumption patterns and identifying opportunities for energy-saving measures.

Labor and Overhead Costs: Evaluating labor expenses and overhead costs associated with THF production facilities.

Yield and Losses Analysis: Examining yield rates and identifying sources of product losses during the production process.

Comparative Analysis: Benchmarking production costs against industry standards and competitors' performance to gauge competitiveness and identify areas for improvement.

Conclusion:

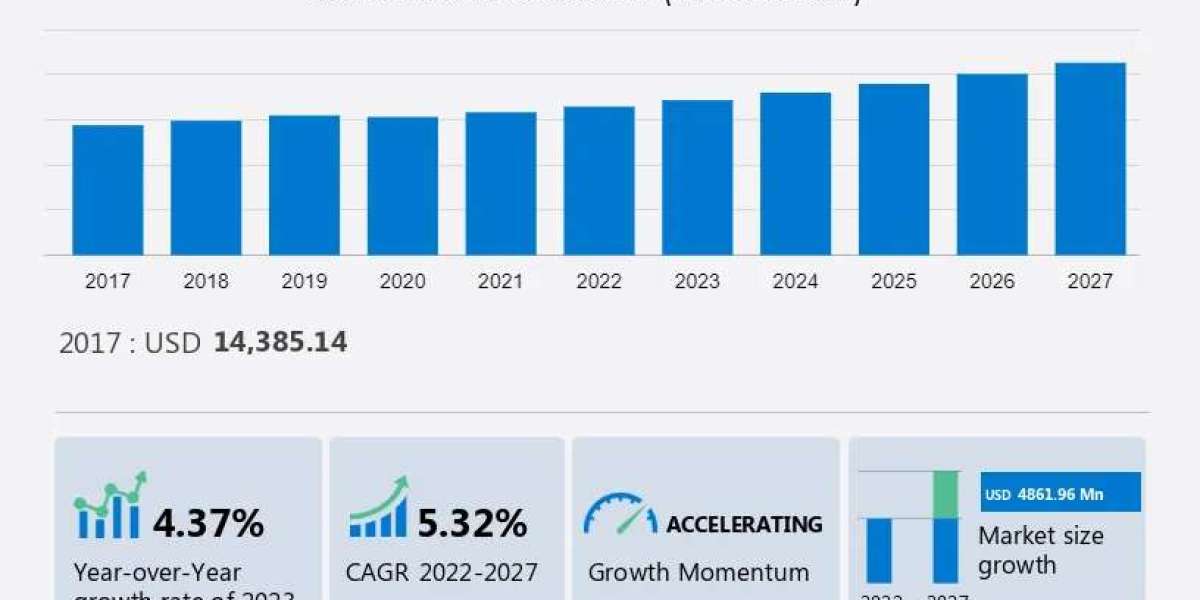

Tetrahydrofuran production costs play a significant role in determining the profitability and competitiveness of THF manufacturers. By conducting thorough cost analysis and utilizing cost optimization strategies, producers can enhance operational efficiency, mitigate risks, and maintain a competitive edge in the market. In an industry driven by evolving market dynamics and regulatory requirements, staying abreast of production costs and implementing cost-effective measures are essential for long-term sustainability and growth.